Bringing Cloud Connectivity to Solar Power Plant Monitoring and Control

Background

In the hot and sunny Tropic of Cancer, a new solar power plant is up and running. The field site for the solar panel installation includes a farm, a lake, and the tops of local buildings. Because solar panels that track the sun's movement can receive 10% to 40% more energy than fixed panels, the system is set up with a central controller for adjusting the panel angles. Additionally, the facility has to record and transmit data about the current energy stability status, as well as check the field temperature and activate the cooling system as needed. If, on a clear day in which the temperature is not too high, power generation is below the set parameters, the system will automatically notify attendants to clean the mirror faces.

The Challenge

At that latitude, heat is a constant problem. Not just because excessive heat affects the power absorbing utility of the solar panel wafers, but also because overheating can damage or destroy the very expensive electrical and networking equipment installed on-site. Another challenge is the remote location of the plant. It was deemed impossible to run network cabling from the local ISP, yet the facility had to be online and linked to the Cloud. For a 4G solution, SIM cards with public IP addresses are prohibitively expensive. Lastly, the system had to be able to effectively connect to a Modbus controller. Modbus is a communication protocol used for transmitting data over serial cables, and many devices in the solar facility used this protocol.

So the solution to be implemented had to overcome or work around these many obstacles.

System requirements include:

- Remote field monitoring and control

- Ability to send alarms to mobile phones

- RS-485 interface and support for Modbus protocol

- Support for MQTT cloud protocol

- Microsoft Azure cloud

- Ability to operate in extremely high temperatures

- Dual cellular cards for redundancy

- Secure VPN tunnels

The Network Solution: Industrial 4G EW50 & EW200

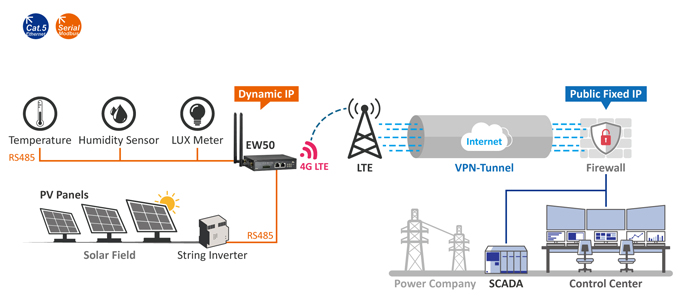

The EW50 is an intelligent industrial grade gateway designed for critical infrastructure and industrial applications. It provides reliable and secure remote connectivity designed for harsh environments, giving operations and IT real-time awareness with remote monitoring. The EW200 is an advanced, feature-rich upgrade of the EW50. It combines IEEE 802.11b/g/n/ac WLAN and 4G LTE cellular technologies.

Both devices provide Ethernet, serial, DI/DO and Modbus bridging, making them ideal for connection to the many inverters, sensors, and other devices on the site. Importantly, MQTT is supported. MQTT is a messaging protocol based on the publish-subscribe messaging pattern. It is the most basic way of communication in the cloud, and one that is ideal for IIoT (Industrial Internet of Things) applications that require active notification.

The benefits of these two solutions were numerous. The Modbus gateway converts Modbus RTU/ASCII to Modbus TCP format. The EW50, installed with a floating IP SIM card, acts as a VPN initiator connecting to a VPN server with a public fixed IP SIM card installed at the power company's remote location for secure site to site communication. Every time the cellular connection is reestablished, the VPN automatically takes effect.

Both the EW50 and EW200 have hardened specifications, allowing for extended long-term performance even in the hottest conditions.

Conclusion

Solar power generation is becoming more widely recognized and utilized as a renewable clean energy source. It is expected that the number of distributed solar plants being built and going into operation will continue to increase. These plants have critical monitoring and management needs, including real-time monitoring and messaging, control of panel tilt, power prediction, and power control systems.

In many cases, traditional wired infrastructure for monitoring and management is not feasible, due to costs or environmental concerns. Equipping these sites with appropriate 4G/LTE gateways is the ideal approach. They allow for remote management by mobile phone, and when equipped with a DI/DO interface can even allow for remote rebooting of an IPC through the DO relay mode. The presence of a serial interface on the gateways can eliminate the need for a PLC, reducing the overall cost.

Related products:

EtherWAN – " When Connectivity is Crucial "

► For more information, please contact: info@etherwan.com.tw