Smart Monitoring Systems for Floods and Droughts in Taiwan

The Power of Smart Monitoring Systems

Smart monitoring systems are gaining traction in flood-prone areas, especially during summer, like river embankments and low-lying regions, effectively mitigating the impact of rising sea levels and global warming. Moreover, these systems also play a crucial role in addressing water scarcity during prolonged droughts.

Taking Taiwan as an example, the country is surrounded by water, making it susceptible to intense typhoons and regional flooding during the summer. Additionally, prolonged dry spells can lead to low reservoir levels, posing threats to livelihood. Consequently, the Taiwanese government faces the challenge of effectively monitoring floods and implementing emergency measures to tackle drought situations.

Monitoring Systems Challenges

Temporary Water Stations During Dry Seasons

Low water levels and insufficient water pressure in some reservoirs can prevent water delivery to households. To address this issue, local governments set up numerous temporary water storage stations that rely on tanker trucks for transportation. However, inspections can only be done manually, resulting in higher labor costs and significant reporting delays.

Flood Control Measures at River Embankment Gates and Drainage Facilities

River embankment pumping stations are typically unmanned and rely on fuel-operated drainage equipment. However, the risk of fuel shortages during critical drainage requires manual supervision, resulting in labor-intensive and time-consuming processes that incur additional costs.

Alert Systems for Flood-Prone Areas

Notification systems and on-site warnings can alert drivers to flooded areas, saving lives and ensuring safety. However, these systems are often located outdoors, making them susceptible to damage from wide temperature variations over time. Additionally, establishing effective wired communication systems over such large areas presents a challenge.

Overcoming On-Site Constraints

Through the analysis in the table below, we can discover solutions corresponding to derivative technologies under environmental constraints.

The proper implementation of related technologies overcomes on-site constraints and provides cost-effective, low-maintenance, and stable operation under varying temperatures (see table).

| Challenges | Solution | Benefit |

|---|---|---|

| Wired system deployment is not easy | Using wireless technology such as NB-IOT, Cat-M1 cellular base stations, remote control can be applied anywhere where a mobile phone can receive a signal. | Reduced infrastructure construction costs |

| Personnel maintenance and management are not easy | NB-IOT and Cat-M1 simplify data volume with low monthly fee. | Reduced maintenance labor costs |

Device power management | LPWA devices are designed for low power consumption and can enter sleep mode | Reduced equipment power costs |

| Sensor power consumption management | Sensor power consumption is often ignored, so the LPWA Device must include sensor power management. | |

| Difficulty obtaining on-site electricity | Battery or solar power solution | |

| Remote control requirements | The collector needs to be able to receive commands from the control center to control DO and Modbus commands. | Remote monitoring and control |

| Immediately judge and react after acquiring data | The event function can set the threshold to link digital out and shorten the upload cycle. | |

| Resistant to harsh outdoor environments | Waterproof and able to function in wide temperature ranges, waterproof grade of IP65, and temperature resistance of -30 ~ 70°C | Stable operation in harsh environments. |

Proper implementation of related technologies overcomes on-site constraints and provides cost-effective, low-maintenance, and stable operation under varying temperatures (see table).

Application of Disaster Response Systems

Below are three case studies showcasing intelligent disaster response systems developed by government agencies to address drought and flood control during extreme weather conditions.

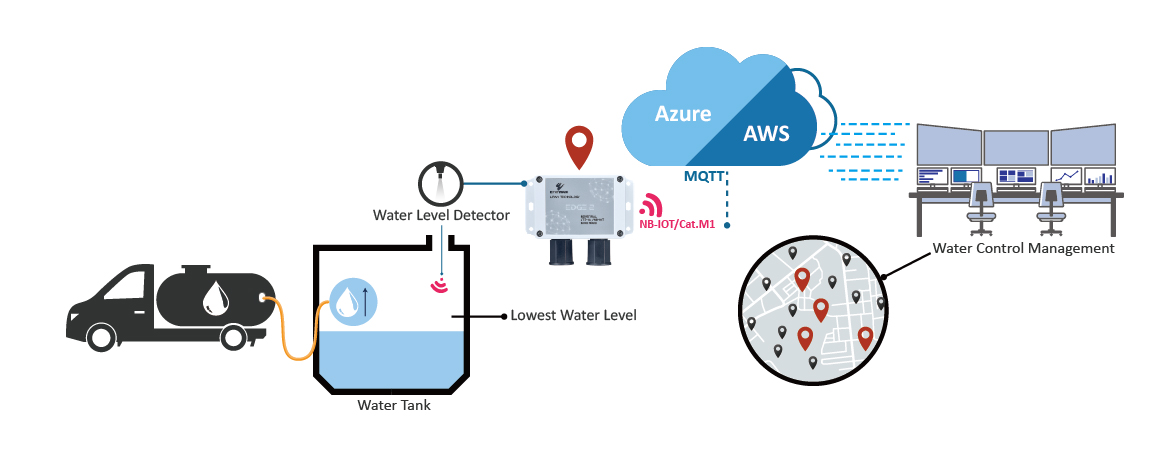

Case 1: Developing a Water Supply System for Dry Season Water Storage Tanks

When the reservoir's water level is low, there is not enough water pressure to distribute it to different areas, causing a shortage of water supply. As a solution, local governments set up large water storage containers in various locations to temporarily meet water demand. These storage containers are equipped with remote monitoring systems that transmit real-time water level data to the water supply unit. Upon receiving an alert for a water shortage, the water supply unit dispatches a water truck to refill the storage container on site.

How does this system work?

After every 10 minutes of sleep mode, the EtherWAN EDGE 2 device equipped with NB-IOT/CAT-M1 will retrieve water data from temporary area water supply storage tanks. Subsequently, the data will transmit to the cloud via MQTT or AZURE/AWS. Once the cloud program analyzes the data, it will send a notification to the water tanker to refill the storage tanks.

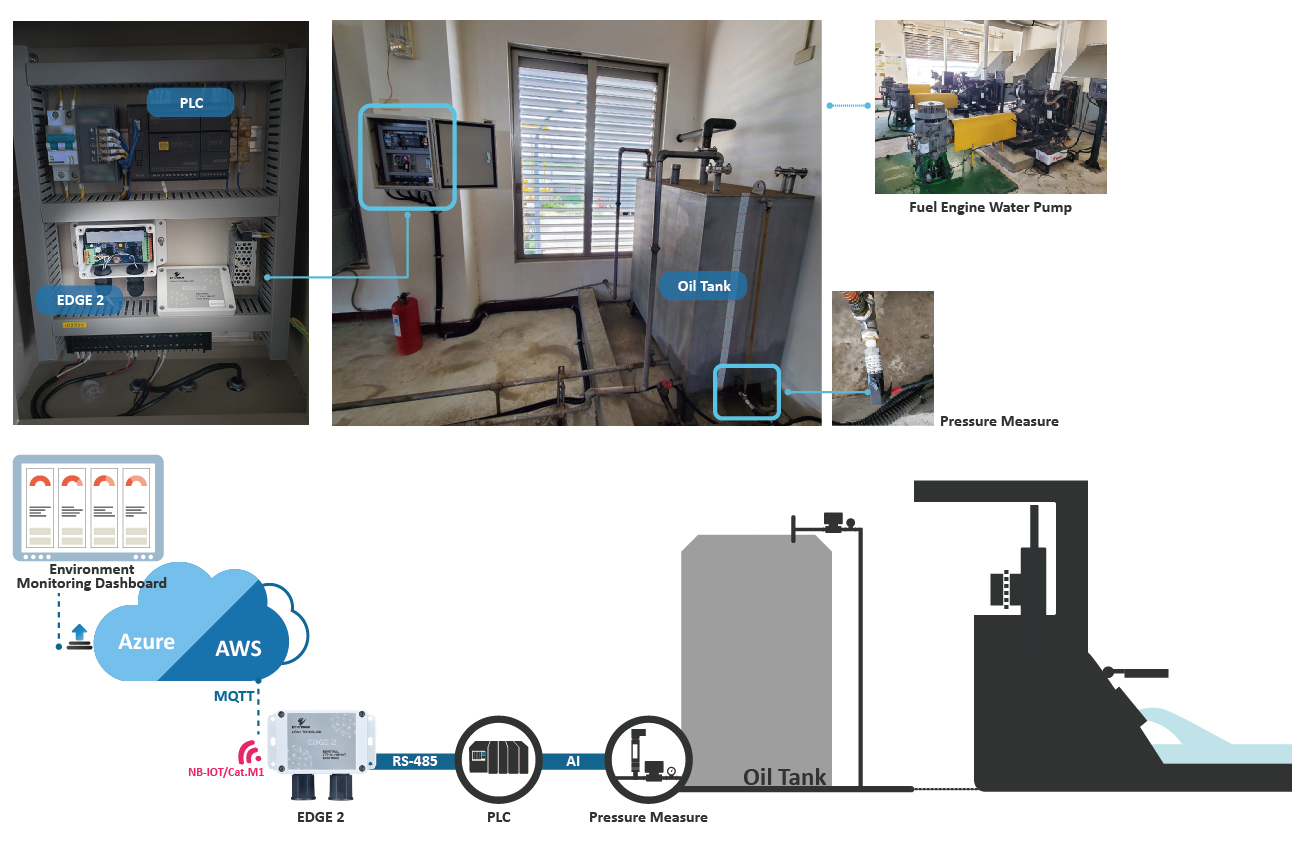

Case 2: Deals with forced drainage equipment’s fuel management

In unmanned flood control pumping stations used as drainage systems, monitoring the fuel tank level is crucial. Fuel levels can decrease over time due to natural volatilization or frequent usage, and it is essential to manage them via remote monitoring for maintenance purposes.

How does this system work?

The EtherWAN EDGE 2 device monitors diesel fuel storage levels every hour and retrieves the PLC pressure gauge data via RS485/Modbus. The gathered data is then transmitted to the cloud via NB-IOT/Cat-M1 using MQTT or AZURE/AWS. The cloud system analyzes the data and dispatches personnel for refueling as required. In the past, diesel storage levels were recorded manually, but with the EtherWAN EDGE 2 device capturing data via the cloud, maintenance, and labor requirements are streamlined.

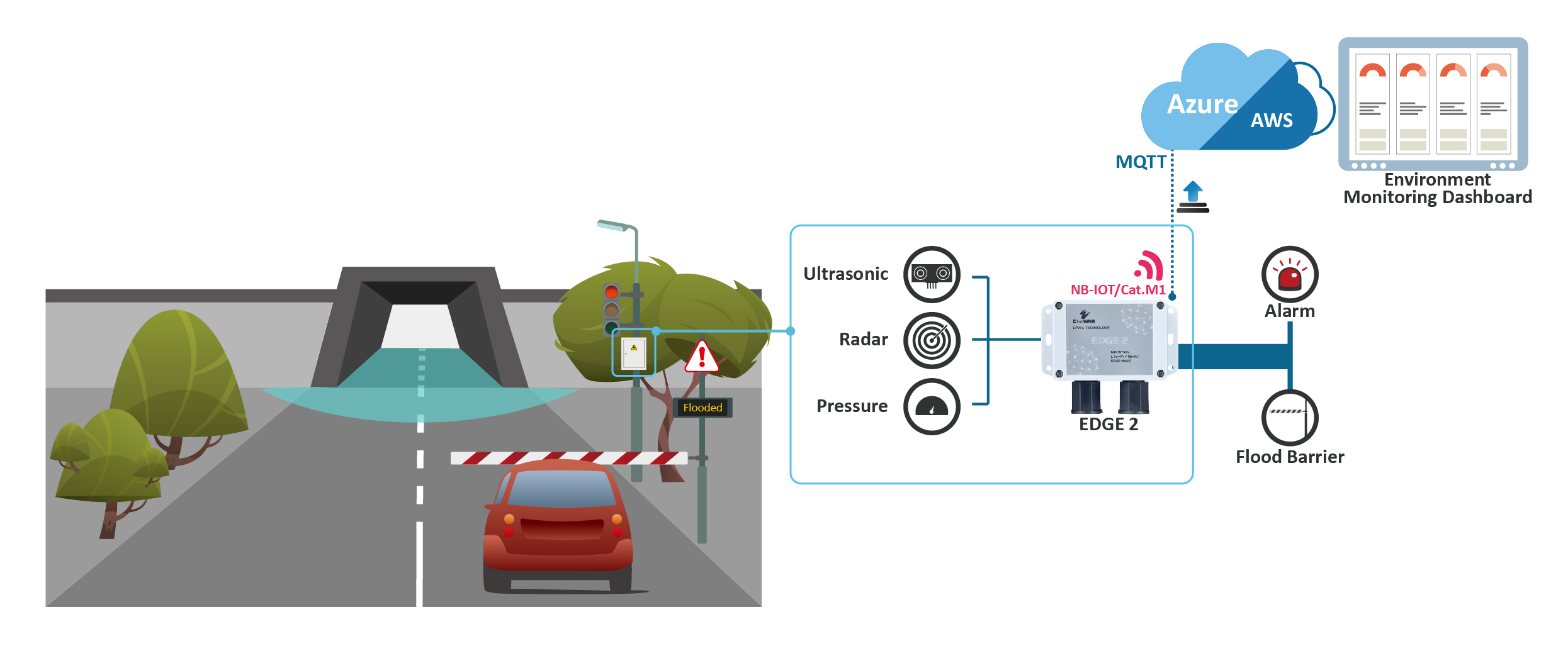

Case 3: Flood notification and river water level monitoring

In abnormal weather scenarios, sudden heavy rains often lead to floods in low-lying areas, putting people's lives in danger. Therefore, the flood warning notification system allows on-site remote monitoring and emergency response in real-time to prevent flood disasters.

How does this system work?

The water level monitoring equipment in low-lying areas is equipped with the EDGE 2, which is in low-power sleep mode. It wakes up every ten minutes to retrieve data from AI/DI/RS-485 sensors, which is then uploaded via NB-IOT/CAT-M1. The EDGE 2 device system concurrently checks if there is any detected flooding on the site. It alerts personnel not to enter and immediately closes the flood barriers. The data capture and upload interval has been reduced to every 5 minutes, allowing for more prompt disaster prevention and control measures to be implemented.

Furthermore, this flood control mechanism has improved its river water level monitoring capabilities. It operates similarly, detecting the water level and promptly activating an alarm when the river water approaches the warning level. This proactive approach helps in minimizing the frequency of disasters.

Note: The EDGE Solution incorporates a 50AH 3.6V battery power configuration. The power control board boosts the voltage to 12 volts, which is then supplied to the sensor. During sleep mode, the EDGE 2 suspends power supply to the sensor to optimize power saving.

Effortless Data Acquisition and Transmission

The EDGE 2 data logger is a potent tool that enhances applications with increased intelligence and versatility. It effortlessly acts as a data acquisition device, querying PLCs and transmitting information via NB-IOT/Cat-M1. Thanks to its wireless transmission capability, there are no issues related to wired deployment. Moreover, the EDGE 2 data logger leverages the low-rate cellular base station of the ISP for data transmission, making it operational in areas with mobile phone signal coverage. This simplifies transmission and significantly reduces equipment construction and maintenance costs.

Related products:

EtherWAN – " When Connectivity is Crucial "

► For more information, please contact: info@etherwan.com.tw