Chile’s Strategies to Maximize Power Plant Reliability and Streamline Management

Chile’s Vision for Renewable Energy

The transition from fossil fuels to renewable energy sources is accelerating in countries across the globe. On a global scale, more power plants are going online that use clean sources than coal and natural gas combined. One of the most popular forms of renewable energy is solar, especially in regions that lack strong winds and large rivers.

In the northern part of Chile lies the Atacama Desert. Its nearly moisture-free climate and year-round sunlight make it an ideal location to construct a solar power plant. The new 110-megawatt plant, Cerro Dominador, is a concentrated solar power (CSP) facility that utilizes 10,600 mirrors (heliostats) arranged in a circle to reflect sunlight onto a central tower 243 feet high.

By heating up and melting the chemical salt inside the tower, the temperature of molten salt can reach over five hundred degrees Celsius. When the water is vaporized, the steam drives the turbines to generate electricity. The plant is designed to store the generated electricity that can provide 24 hours of power.

However, each heliostat needs to be connected and controlled by a central server. It involves a massive data transmission activity.

Balancing Performance and Budget Constraints

To maintain continuous energy production, the solar plant must be able to run non-stop at all times when sunlight is available. The efficiency and profitability of the plant depend on the solar radiation staying focused on the tower. Electrical output will decrease if the temperature of the chemical salts is reduced, and the heliostats must be constantly aligned correctly with the sun and the tower.

The positional adjustment of the heliostats is automated and monitored by an engineering crew at the control center. Heliostat Control Boxes (HCB) receive sun position information from central servers and determine the angle of heliostat arrays at any given moment based on the commands from the control center. This interconnected system requires a redundant, economical, and robust Ethernet solution that is easy to set up and manage to maximize productivity and minimize the chance of costly plant downtime. Due to budget restraints, it is not possible for managed Ethernet switches to be used throughout the entire facility. The solution to be provided required a mix of managed and unmanaged switches, with no sacrifices in performance.

Additionally, the temperature in the Atacama Desert can reach highs of around 104°F (40°C) during the day to temperatures of 41°F (5°C) or below at night. The network infrastructure of a facility running in such harsh conditions must be a hardened-grade to endure sudden temperature swings.

Application Requirements

- Network redundancy with low failover time

- Reliable connections to heliostat control boxes

- Hardware must be able to withstand extreme temperature swings

Robust Network Architecture for a Massive Solar Farm

EtherWAN took on the responsibility of establishing a robust data communications network capable of seamlessly linking all devices across an expansive 700-hectare (1730-acre facility. Collaborating closely with the plant designers, EtherWAN’s field application engineers delved into the intricacies of the application requirements. Subsequently, they meticulously designed and tested the proposed network architecture.

The Right Combination of Hardware and Software

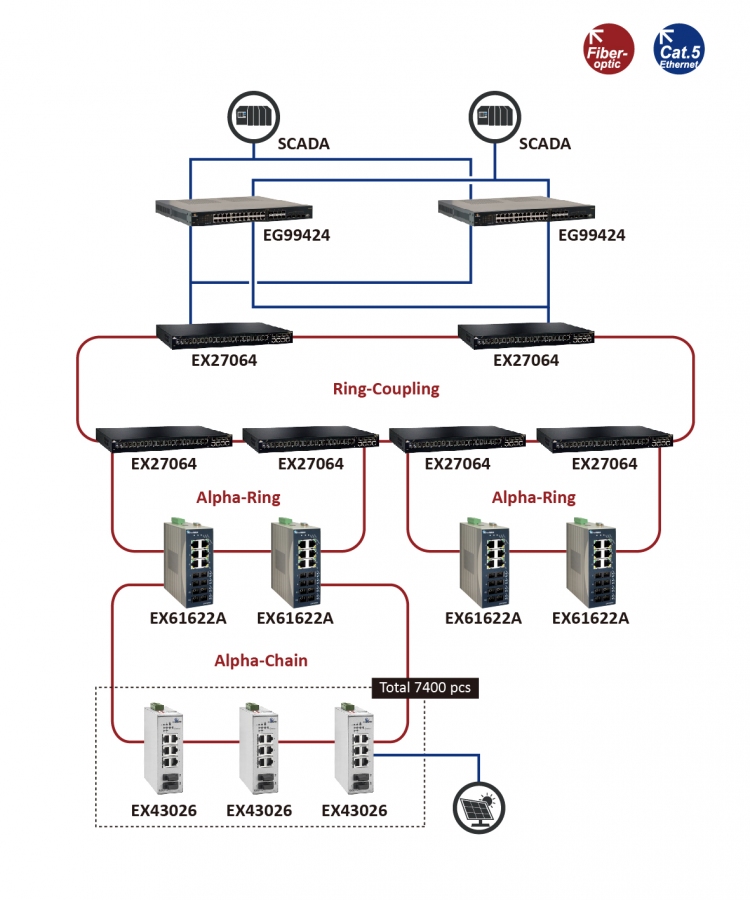

Drawing upon years of experience and proprietary technology, EtherWAN successfully delivered a high-performance solution that fully realized the primary technical objective–ensuring reliable data transmission for over 10,000 HCBs in the solar farm to servers and personnel in the control room. Each HCB is linked to an EX43000 industrial unmanaged switch that is equipped with relay alarms for power and link failure. The EX43000 switches are organized in an Alpha-Chain, a self-healing technology developed by EtherWAN to provide redundancy in complex networks. Based on a user-defined timeout count, Alpha-Chain, which is compatible with other redundancy protocols, enables quick fault recovery.

Each Alpha-Chain is linked to a pair of EX61000A industrial managed switches, interconnected with EX27000 all-fiber interface managed switches into an Alpha-Ring. Alpha-Ring is a proprietary EtherWAN technology that provides a failover time of less than 15 milliseconds in the event of failure of any component in the ring. Through the Alpha-Ring, control room servers are connected with redundant backbone connections.

Full System Protection, Inside and Out

This robust topology is augmented by complete broadcast storm protection. Broadcast storms are caused by an excessive buildup of broadcast network traffic. If left unchecked, a broadcast storm can cause a network to crash. EtherWAN provided broadcast storm protection on both the managed and unmanaged switches employed, ensuring that once the broadcast traffic exceeds a set threshold, broadcast frames will be automatically filtered out. This allows for bandwidth to be conserved for essential transmission.

All three models of EtherWAN switch employed in this solution are hardened against extreme temperatures and are designed for years of nonstop data transmission at a full range of data loading.

Related Products:

Ensuring Reliable Energy and Uninterrupted Connectivity

The migration to solar energy brings new challenges for network design and implementation. For tens of thousands of linked devices, maximum uptime is still essential. Furthermore, no single point of failure can be allowed to cause an interruption in the control mechanisms. To ensure maximum productivity and reap the maximum benefit of the transition to solar power, hardened high-quality industrial network components must be implemented in chain and ring redundancy topologies to prevent system interruptions. When executed correctly, these factors will help lead the world to a cleaner and greener future.

EtherWAN – " When Connectivity is Crucial "

► For more information, please contact: info@etherwan.com.tw